SKY-T-102 Telescopic Stadium Seat

Sky-T series telescopic stadium seats are products designed for all kinds of use, with a folding system that works with with a weight-activated spring system.

Sky-T series telescopic stadium seats are manufactured according to the specifications for indoor or outdoor use. Sky-T series telescopic stadium seats are highly resistant to hooliganism in accordance with EN 12727-4 standard, thanks to its patented single-piece weldless sheet metal structure. Sky-T series is a high-strength telescopic stadium seat series that meets the requirements of FIFA, UEFA and other international sports federations. Sky-T series telescopic stadium seats aim to provide a comfortable experience to users thanks to their ergonomic structure.

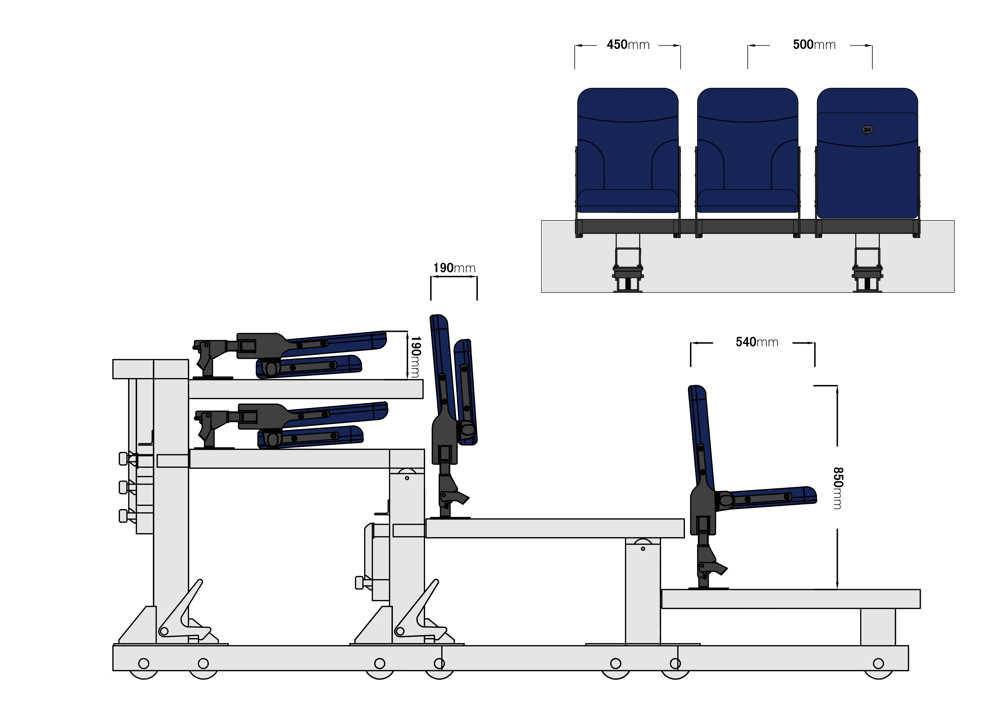

Sky-T-102 telescopic stadium seat is mounted with sleeper (rail system). The sleepers are mounted the floor. Thanks to the sleeper system, the seats can be fixed easily and quickly. Thanks to the sleeper system, the seats can be fixed easily and quickly. Thanks to this system, it is possible to adapt the space to the desired capacity, to adjust the distance between the seats or to make possible product and layout arrangements easily. Thanks to the spring closing mechanism located on the traverse legs, the seat folds and enters the telescopic system. The seat opens and closes with the weight-activated spring system operating inside the seat font. Thanks to its weight-activated spring system, Sky-T-102 telescopic stadium seat is maintenance-free throughout its lifetime.

Cast polyurethane sponge is used in the seat and back font of the seats and there is a metal frame inside. The polyurethane and artificial leathers used are manufactured with non-combustibility additives. 4 mm lamination is applied to the furnishings used in the Sky-T-102 telescopic stadium seat. The furnishing area on the back font allows logo and advertising applications. The furnishing used in the seats is manufactured with additives resistant to UV, abrasion, chlorine and combustion. Thanks to the thin structure of the seat, it is possible to relieve the circulation on the steps and increase the capacity.

Technicial Specifications

- Seating and backrest units of the seats are 50+- 10% density polyurethane filling sponge on metal frame.

- It is in compliance with the EN FMV SS 302 standard with non-combustibility additive.

- It is corrosion resistant in accordance with EN ISO 9227 standard.

- It is highly resistant to hooliganism in accordance with EN ISO 12727-4 standard.

- Artificial leathers used in furnishings are manufactured with additives that provide high resistance against salt, UV rays, fire and chlorine.

- Artificial leathers used in furnishings are covered with non-combustible 4 mm lamination.

- The seats have a folding mechanism that works with weight-activated spring system.

- The metal parts of the seats are designed and manufactured from 6 mm one-piece sheet metal without welding, by laser cutting and bending in press molds.

- The seats are firmly attached to the barriers mounted on the steps with a sliding system. With this system, fewer screw anchors are used on the steps, it provides the opportunity to slide the seats to the right and left, and the seats can be easily replaced with new ones in the future.

- The seats increase space in the tribunes thanks to their ergonomic and thin structure.

- The backs of the seats are suitable for logo and advertisement embroidery application.

- Seat numbering area under the seat is available optionally.